Urgan is also a versatile design studio where design and craftsmanship coexist. With its eclectic and unconventional approach to design, UR Studio is devoted to create bespoke solutions, beautifully imagined and seamlessly implemented, able to meet the desires of refined clients throughout the world, interpreting their own needs and delivering unparalleled services . We take advance of a global sourcing and we provide to your own creative team a selection of local suppliers, materials swatch cards, soles and shoes accessories.

We take advance of decades of experience in the sector to offer you a global sourcing. We are proposing or sourcing based on your references, raw materials, Pu’s, leather and all the shoes components and accessories from the local market, as well from our suppliers in China, Spain and Italy.

A skilled stuff of developers constantly follow up our customers, being able to be a real connection between your creative team and our sampling room.

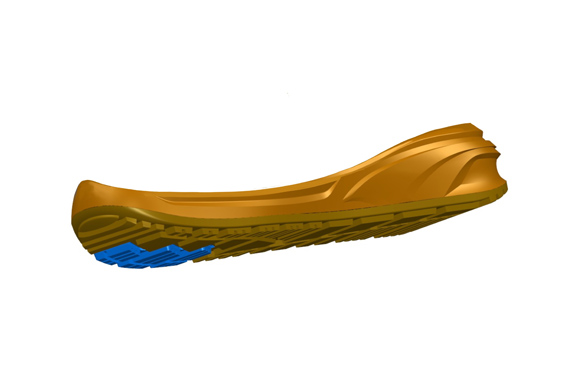

Taking advance of the most innovative technologies, we are able to create your pattern cut, mock-up, last and sole development until arriving to a technically perfect final product.

We are able to provide 3D drawings and mock-up to realize your sole and develop it with your design team before the preparation of the real mould.

A dedicated 100 sqm meeting room to plan with your stuff all the steps from sampling to production and delivery, it is everyday at disposal of our customers to build together the right synergy.

We offer the chance to put at your disposal the introduction of your collection, a thematic showroom with buffet service integrated and chattering organization, according to your needs and preferences.

Urgan Footwear company have a proactive Quality Assurance system with quality control (QC) inspections at all stages of the production.

The Independent QA Department work totally independently from the production team and report directly to Factory Management .

Quality Control Management plan steps are below

- Incoming Inspection

- Pre-Production Process and meeting

- Cutting Process Inspection

- Print Processes Inspection

- Upper Stitching Inline , Initial and Final Inspections

- Assembling Inline , Initial and Final Inspections

- Broken Needle and Sharp Object Control

A trained stuff of chemists is at your disposal to test all our production, making us able to control and certificate our items.

With a dedicated covered area of 1.500 sqm, we take care of your products until the shipping, making sure that the goods are well produced, that they have passed our tests and quality controls and that they have been packaged in the safest way with all the necessary paperwork, requested from your company to guarantee your order a safe and fast shipping.